The Gibran Sculpture Series

Here we are, weeks down the line and many, many steps, and we still haven’t seen anything that’s recognisable as the original clay sculpture yet. This is where it starts to come together at last!

To remind you, this is what we are starting with…

Some of the components of Spirit of Freedom in a pile on the floor.

The assembly process…

To assemble the complete sculpture, the individual cast components need to be ‘glued’ together. This is done with a two-step argon welding process. Two castings are put together so that their edges meet as closely as possible. The fit ought to be very close to perfect, because after all, that’s how the castings were made in the first place. Then they are spot welded just to hold them together mechanically while the ‘seam’ or ‘join’ is finished by a continuous weld to give the greatest strength as well as making the join invisible.

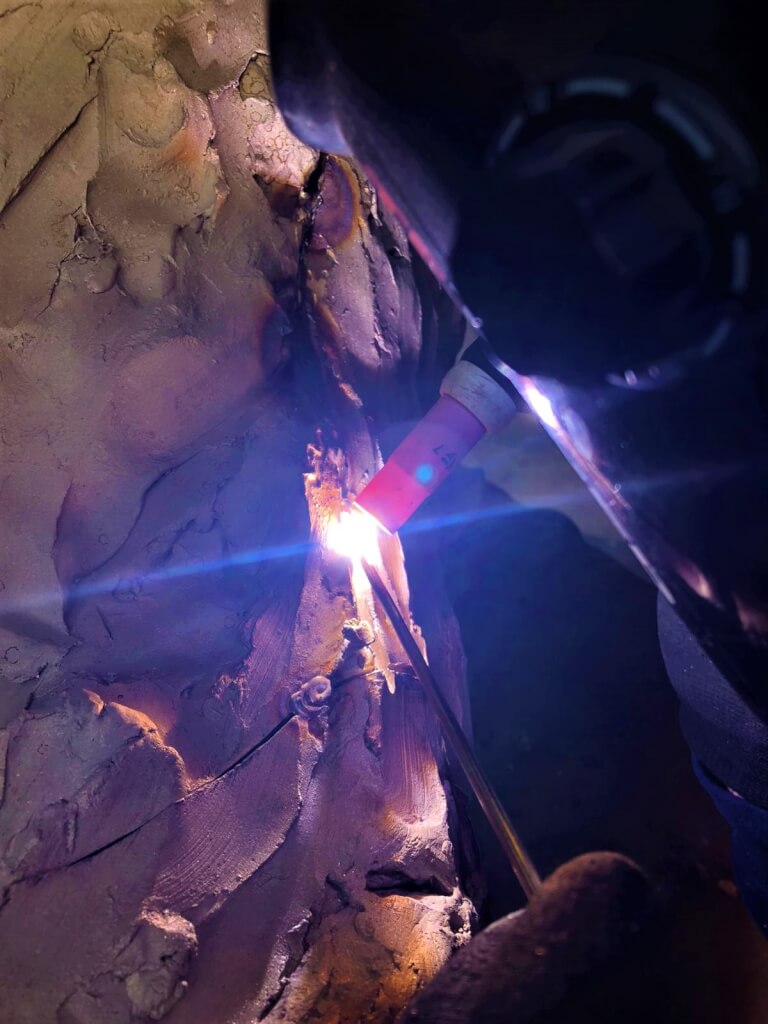

In the photo below, you can see a thin, snaking gap between two sections. The welding torch and the rod are being used to create a continuous weld all along the joint.

Just below them you can see a spot weld, holding the two pieces together.

Here, individual castings have been fitted together and then spot welded to hold them in place. This photo shows the bottom section of the sculpture having the joints continuously welded to hide the join between the castings. The sculpture is resting on a workbench in the workshop. The background is the windows of the workshop.

This photo is a close up of the continuous welding process. It shows two sections of the sculpture being welded to hide the join between the castings. In case you can’t work out what you are looking at, the craftsman is standing on the right of the picture. His left hand is at the bottom right of the picture, holding the welding rod which appears to be pointing upwards towards the heat. His full-face protective helmet is filling the right-hand edge of the photo. A little below the current welding focus, you can see a small spot weld which is holding the castings in place until the continuous weld is complete.

This is a close-up of the inside of the base of the sculpture. It shows three castings which have been welded together. There’s a large casting that runs from top to bottom of the left hand side of the picture and then two others held against it, one top right and the other bottom right. There red-hot heat spot is where the three edges meet in the centre of the picture. Daylight is flooding into the cavity of the sculpture from the bottom right of the picture.

This photo shows the mid-section of the sculpture fully assembled and fully welded. This section is the piece between the bottom of the neck and the very tops of the raised arms down to the bottom of the torso. It is propped up, on the floor of the workshop with oxygen, acetylene and argon rubber welding hoses. As you can see, it is a very pale bronze colour at this stage of the process. The brighter, horizontal hooped line is where the joint across the waist has been continuously welded.

This is the bottom half of the sculpture resting on its side on the bench in the workshop. This section is the section from the feet, or base, to the tops of the thighs. The assembly of this section is complete and a specialist is now removing any excess metal left over from the welding process to ensure that the complete assembly matches the original wax and clay sculpture.

The operator is using an angle grinder. Behind him is the back wall of the foundry, with a furnace on the far left and behind that a large galvanised hopper with, to its right, a set of concrete steps going up.

See the finished Speak to us of Freedom sculpture here.